How to choose a supplier in B2B: tips and techniques. Part 1: Assessing product quality

Choosing a reliable supplier in B2B (businss to business) is one of the main tasks of any procurement manager. After all, the wrong decision can lead to delays in deliveries, increased costs and even to the failure of the entire project. And solving this task is not easy and not very fast.

Usually primary information includes such data: name, contacts of suppliers, availability of necessary items, prices for these items, their availability. – Collected, compared.

But how to make a final choice?

If we are not talking about a one-off small purchase, it is necessary to make a more in-depth assessment. An experienced supplier knows how to choose the right supplier and does it according to several criteria.

Criteria for assessing the reliability of a B2B supplier

- Product quality

- Reliability and stability of supply

- Price level and payment terms

- Flexibility and adaptability

- Technical support and service

- Reputation and feedback

- Financial stability

In this article, let's look at the product quality indicator when selecting a contractor.

Product quality

Why is it considered to be the primary indicator that should be at the centre of attention when choosing a supplier? Because, on the one hand, it determines the financial costs of B2B purchases and, on the other hand, it directly affects the sales of your products. For poor quality components, for example, industrial locks or handles, can lead to breakdowns, higher repair costs and a lower reputation in the eyes of your end-users, even to the point of their abandonment.

Assessing product quality

To ascertain the quality of products, such criteria are checked and the following methods are used:

- presence of certificates,

- availability of documents officially confirming the origin of the product,

- compliance with international and industry standards,

- product testing,

- other methods of quality assessment.

Certificates

Certification of hardware products is not mandatory in Ukraine. But you can ask your supplier to order a certificate from the manufacturer.

Official origin of products

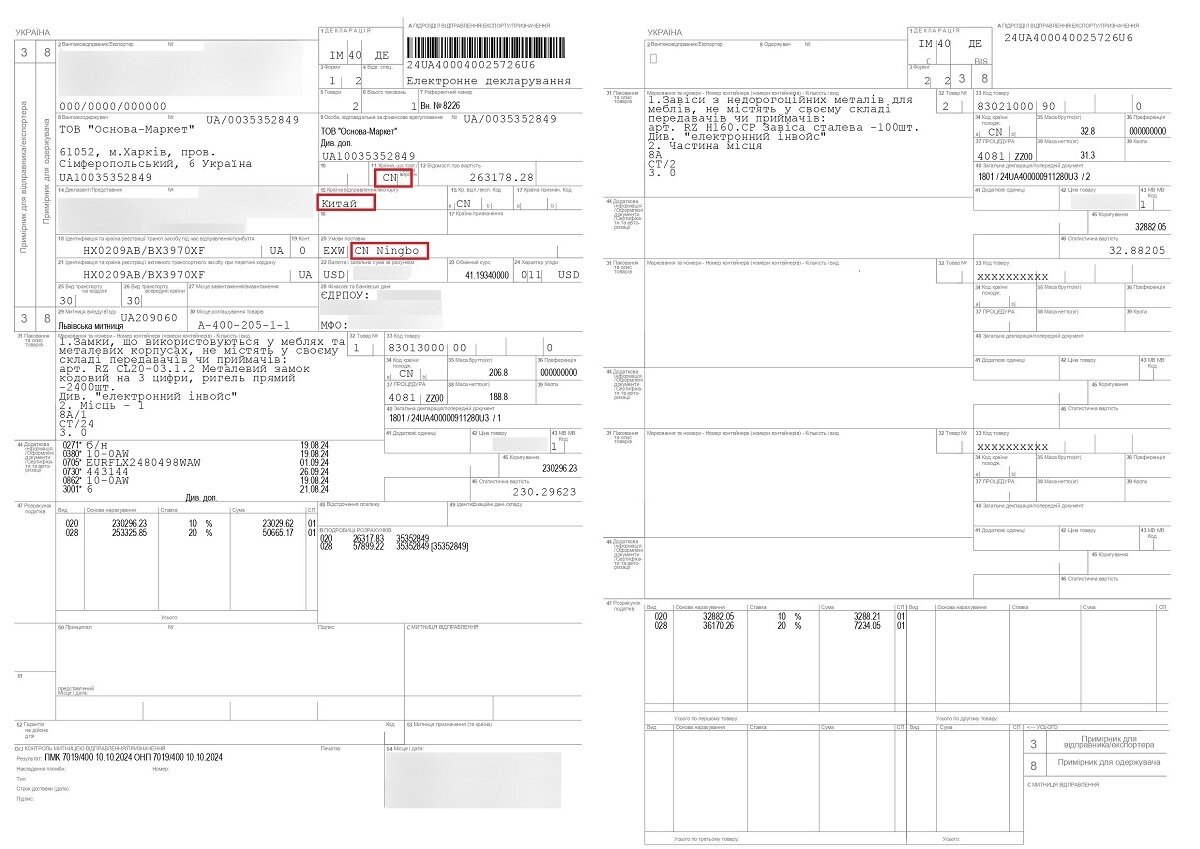

You can ask us for a copy of the customs declaration, which indicates the country of origin of the goods and the sender — the manufacturer (see on screens).

Example of a customs declaration

Compliance with industry and international standards

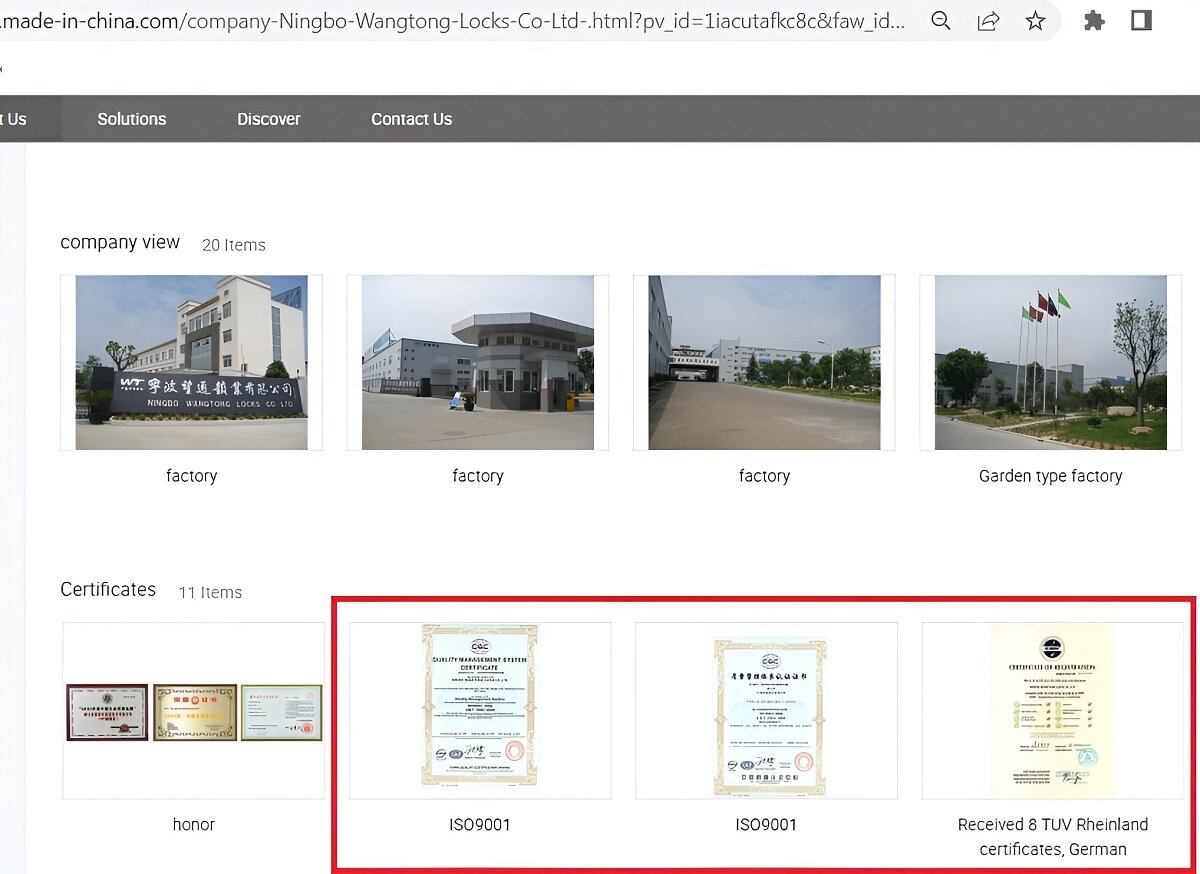

A responsible B2B supplier focuses on product compliance with international standards when selecting an industrial hardware manufacturing plant. For example, we at RZ-market most often choose a company that is ISO 9001:2015 compliant, which implies compliance with specialised industry standards as well.

Information about this can be found on the corporate web resources of a potential partner or on large B2B supplier search sites.

Example of data about a verified supplier on Made-in-China

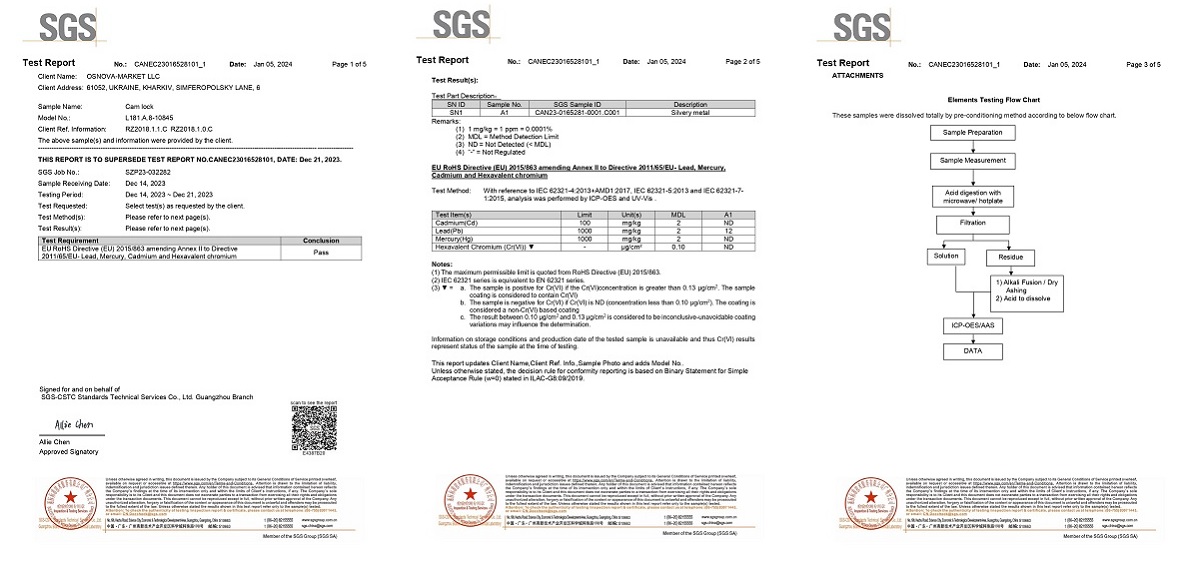

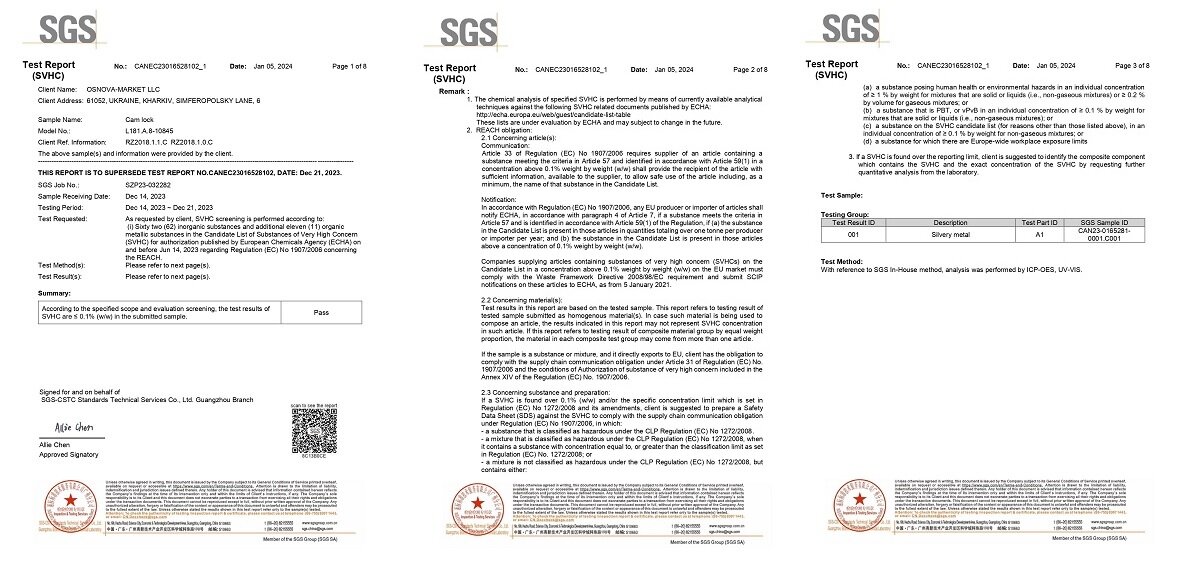

We also pay attention to RoHS and REACH certification (see below).

Testing

Testing to determine product quality can be carried out in several ways:

- in your company's laboratory;

- n the laboratory of an industry association or in state metrology institutions;

- in the laboratory of the manufacturing plant.

We at RZ-market prefer the last method. At our request, the factory conducts in-depth studies of product samples from the supplied batch.

Example of RoHS certificate for a post lock RZ L2018.1.1.C

Example of REACH certificate

Other methods of product quality assessment

Visual assessment

Products can be assessed purely visually and tactilely: products should look attractive, surfaces should be well finished, smooth to the touch and free of burrs.

If a part is designed to turn, it should move without obstruction. For example, the key should turn in the lock insert.

Lock assessment

The hinge must turn to the designed opening angle. The pivoting handle must deflect to open the lock insert. The rubber door gasket must fit snugly around the edge of the metal door. The self-adhesive seal must be securely fixed to the surface with an adhesive layer.

The powder coating or galvanised coating shall be free of defects in the form of stains or irregularities. The surface of the castings must be free of caverns and free of swellings or bubbles.

We carry out a visual assessment using product samples received by post or during a factory visit.

Statistical quality control

Using this method, we calculate the percentage of defects in the batches received, based on complaints from our customers: if it is higher than 5% (which is considered to be the acceptable norm for our products),

then we break off relations with such a manufacturer.

The calculation is performed according to the formula:

Percentage of defective products = (Number of defective products / Total number of products in the batch) * 100%

In-process control

We selectively carry out quality control at the production site when visiting the factory.

Acceptance control

When goods arrive at the warehouse, the storekeeper carries out selective quality control of the received products on the basis of visual inspection.

In this way, we carry out a comprehensive assessment of the quality of products from our suppliers. Therefore, working with us, you can be confident in the quality of purchased components.

Author: Andrey Alekseev

Read about how to find a foreign supplier in B2B in our other article:

20 sites for finding B2B suppliers in international markets