Organisation of customised deliveries from overseas plants

Among the services we provide, there is the production and delivery of products to order from foreign enterprises.

Let us tell you more about this service.

From which countries can we organise direct deliveries?

From China, Turkey, Sweden and other European countries.

Is it possible to find a foreign partner on your own?

Yes, of course. Sooner or later such an idea - to reduce the costs of production of their own products by importing components - comes to the mind of any furniture manufacturer.

The question is how to put it into practice. And there are several options for you:

- place an order at a foreign company yourself;

- find a company that carries out a wide range of supplies, with expertise specifically on imports;

- find a company that imports furniture fittings.

Option three is to work with our company. We are both a manufacturer, importer and distributor of industrial hardware for industrial metal furniture in various industries.

What are the specifics of import deliveries?

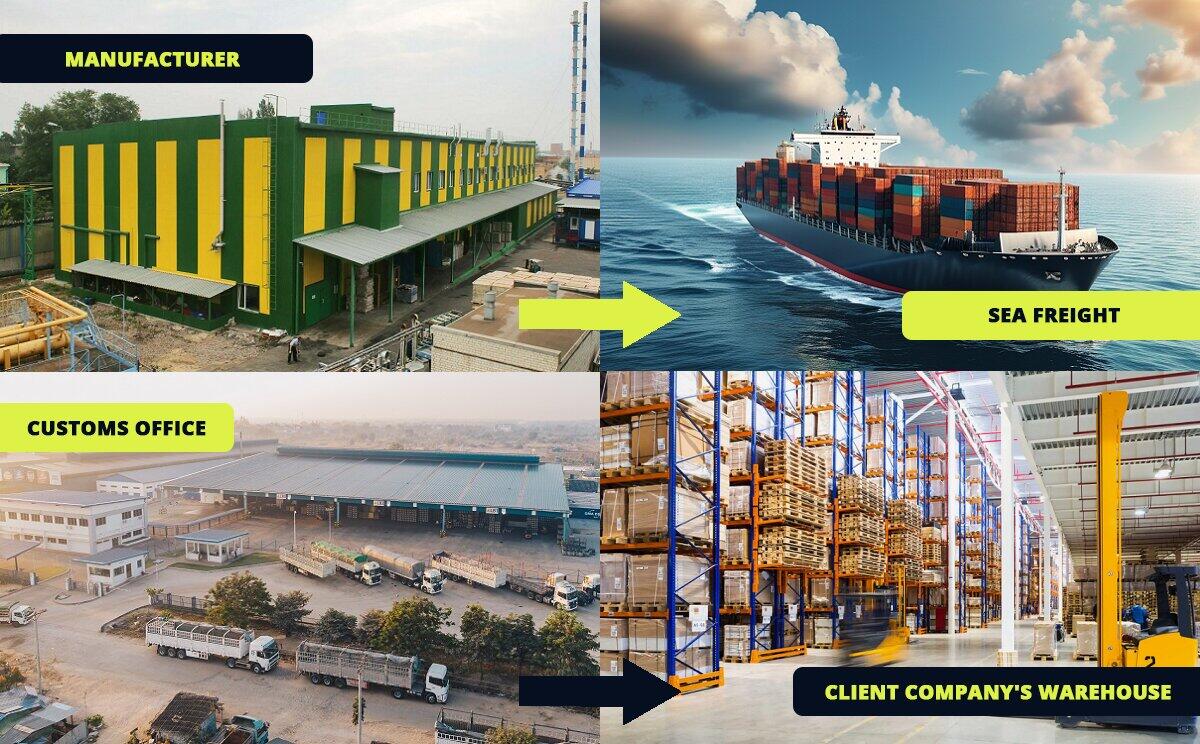

If you enter a foreign market on your own, you need to perform several stages of work of varying complexity and duration before you receive the necessary products in your warehouse.

Finding and evaluating a supplier:

1) Know where to look for good suppliers. It is better to select proven, and it is those who specialise in the production of the fittings you are interested in;

2) analyse suppliers according to certain criteria, establish direct contacts with them (language barrier) and finally make a final choice online;

3) travelling abroad and a face-to-face meeting. Excursion to the enterprise, negotiations. Assessment of compliance of information received remotely and actual production conditions and technologies.

Placing an order:

1) communicate to the factory receiving department what, in fact, you need (language barrier);

2) agree on the conformity of your standards, TU, specifications and factory standards;

3) the ordered batch of goods should be of industrial volume, i.e. not less than the volume determined by the factory;

4) make 100% prepayment;

5) take the manufacturer's word for it that he will adhere to the terms of your order. If not, someone has to control these deadlines.

Logistics:

1) verify that it is your order that has been shipped from the factory;

2) check that the order is delivered to the port and loaded on the container. Make sure that the goods in the container are securely fastened, otherwise a pile of scrap metal will arrive;

3) track the arrival of the container to Poland (if the cargo is from China). There it is reloaded onto a car and proceeds to the border;

4) track customs clearance (sometimes there are issues of delay or even confiscation of goods);

5) receive the shipment at your company's warehouse;

6) process the arrival of the shipment.

Storage:

1) you need to have sufficient storage space to store the components;

2) components are stored until they are used in a new project in your production facility.

Financial costs:

1) due to the requirement of industrial order volume and 100% prepayment from the manufacturing plant, it is possible that you will have to take a loan from the bank; this entails paying monthly % to the bank on the loan;

2) additional costs for payment of FEA specialists. On the side of your company it is a manager, an accountant, a translator, a customs declarant, a lawyer. On the side of the country of manufacture you should also have your representative to solve various issues (see the stage of placing an order, point 5; stage Logistics, points 1, 2);

3) а long return on investment period. This includes freezing your funds for 3 to 6 months until the goods arrive. Then, until the new project is implemented and payments for it arrive, there is no return on the investment invested in these components;

4) payment from own funds for spoilt goods (possible defects from the manufacturer plus damage to the cargo in transit).

Conclusions

For a newcomer to these issues, there are too many uncertainties, too many risks, too high costs.

At the same time, all these issues have already been worked out in our company. Because we have import orders on stream: we have an average of 6-7 deliveries per year.

And when working with us you only need to make 2 contacts:

1) call our manager;

2) sign an additional agreement.

Then you have:

- No 100% prepayments, no disputes with the factory-manufacturer, in the port of shipment, at customs.

- No arrival of low-quality products.

- No payments for foreign trade specialists, no monthly payments for credit, no problems with storage of components.

This is how our regular customers – leading manufacturers and consumers of industrial metal furniture – work with us. Contact RZ-market! A team of professionals is waiting for you!

Author: Andrey Alekseev